How it Works

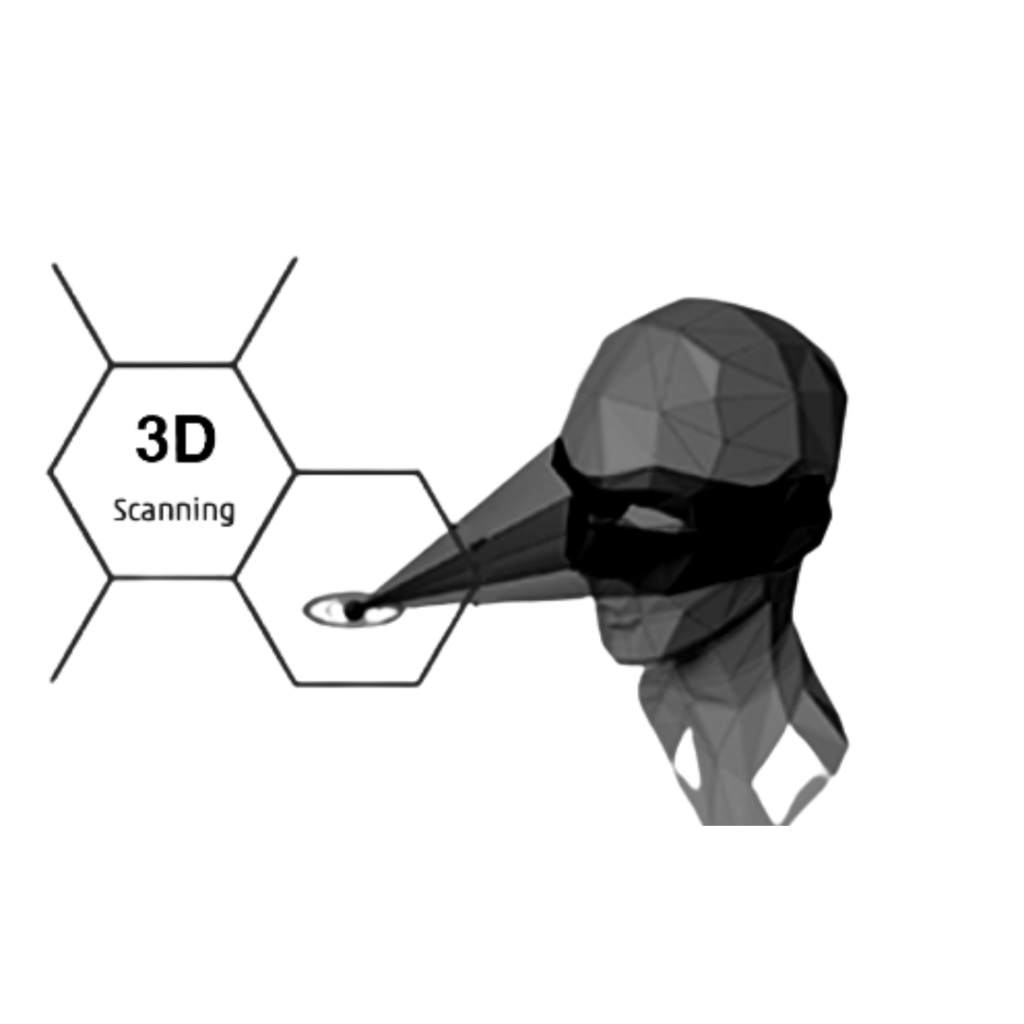

3D scanning.

A infrared 3D scanning is done to capture your unique face topography. The basis for each custom tailored eyewear frame is the recording of the customer´s individual face topography. As we use the newest generation of infrared scanning technology we guarantee the highest scan precision. This scan forms the foundation for each individual frame.

Custom Tailoring

Original design – individually fitted. Our self-developed algorithms work magic in that they enable the customer to have each frame dynamically adapted to each individual´s face topography, without losing the character of the original design.

Design & Manufacturing

All of our designs are technically and dynamically optimized based on the analysis of hundreds of faces. The basis for the design is the average face geometry of the target customers. The final product is a unique symbiosis between human, science, craftsmanship and technology. Further additive production technologies are enabling the individual production of complex structures with materials that are 30% lighter than acetate and significantly more durable.

DESIGN

Our designs are refined with advanced technical and dynamic optimization, derived from data analysed from hundreds of facial measurements. We use the average face geometry of our intended customers as the baseline for our designs, producing an ideal synthesis of human artistry, science and technology.

SCAN

We use the latest infrared scanning technology to measure the unique features of your face, creating a custom tailored eyewear frame for maximum comfort. This scan provides the foundation for a perfect fit.

CUSTOM TAILORING

Original design – individually fitted. Our self-developed algorithms work like magic. They enable the customer to have each frame dynamically adapted to each individual´s face topography, without losing the character of the original design.

MANUFACTURING

MONVUE made in Germany stands for the highest quality, manufactured with the most advanced production technology of the world. Further additive production technologies are enabling the individual production of complex structures with materials that are 30% lighter than acetate and significantly more durable.

GO TO MARKET

Delivery time for a custom-tailored frame is between 3-6 weeks. We issue a satisfaction guarantee to each customer on the fitting of the custom-tailored frame.

Unique Face Topography

Self-developed algorithms enable to have each frame dynamically adapted to each individual´s face topography

The final product is a unique symbiosis between human, science, craftsmanship and technology.