The production of waste is a common occurrence in every industry, including the eyewear industry. However, the impact and contribution of this industry often go unnoticed, evading accountability for its role in global issues. At the outset, we believe that waste is not a problem, but rather a valuable resource. As a result, we are committed to reducing our waste and strive to be a zero-waste company. In this regard, we aim to provide insight into the measures we’ve taken so far and the progress we’ve made in our journey toward achieving this goal.

- Minimizing waste in the eyewear industry

- Implementation of changes to reduce waste

- Ongoing efforts to further reduce waste

- Creating a closed-loop system to minimize waste

Minimizing waste in the eyewear industry

In 2017, it came to our attention that the eyewear industry is producing a much larger amount of waste than previously realized. We were disheartened by the lack of effort and progress being made toward creating a more sustainable industry. It was frustrating to see that this issue was not being openly discussed by some of the largest eyewear corporations, which our families have been patrons of for generations. There may be a lack of understanding or awareness of the environmental impact of this kind of manufacturing. Alternatively, profitability is prioritized above the well-being of both people and the planet.

PROFIT > PEOPLE > PLANET

In today’s world, information is in abundance, and knowledge equals power. Whether as companies or individuals, we have the freedom to inquire, decide and act based on the facts available to us. We must take responsibility for our actions and the impact they have.

As a small company, MONVUE is grateful for the agility that comes with its size, enabling it to swiftly address issues as they arise. The current challenging times have underscored the importance of change; specifically, transforming our consumption habits. To achieve this, corporations must prioritize people and the planet, over profits, in the creation of their products.

Monvue’s belief

PLANET > PEOPLE > PROFIT

Monvue is leading the way in combating unsustainable practices within the lenses and frame industry. By manufacturing sustainable bio-based frames, we are actively reducing the reliance on petroleum-based plastics.

Bio-based materials are derived from renewable resources, such as plant-based polymers or biodegradable materials, which significantly reduce environmental impact and greenhouse gas emissions. Our commitment to sustainability extends beyond the materials used; it also encompasses the entire lifecycle of the product.

Implementing effective recycling programs and manufacturing technology puts the planet first followed by delivering the most exceptional quality of frames in terms of fit, design, and durability which gives the customer an excellent experience!

WHAT MATERIAL IS USED TO MAKE EYEWEAR?

In essence, eyewear frames consist of a frame front and the temples which are manufactured using plastic or a similar substitute, with metallic components such as hinges and wire cores. Additionally, lenses are a vital component of the frame. Generally, frames are produced using cellulose acetate, a robust and visually appealing plastic-like material derived from cotton and wood pulp.

The issue at hand is that a substantial amount of acetate used to manufacture eyewear frames goes to waste, with up to 80% being either incinerated or sent to landfills by factories and brands worldwide. As a small company, this is unacceptable to us, and we are committed to achieving zero waste in the eyewear industry. While we recognize that this is a difficult feat, it remains our ultimate goal. To achieve this, we are striving to implement a closed-loop system and exploring alternative manufacturing methods such as 3D printing that will enable us to recycle all waste generated.

Implementing changes to reduce waste

In line with this belief, we have had to reassess our entire product journey and implement some proactive changes. The following is a summary of the measures we have taken to minimize our environmental footprint and utilize materials that would typically go to waste.

3D-printed Eyewear with Sustainability at its Core

As consumers become more aware of their carbon footprint, the demand for sustainable and eco-friendly products has been on the rise. This is where Monvue comes in – as a sustainable 3D-printed eyewear company, we aim to make a difference in the industry and the environment.

One of how we achieve this goal is through the use of biobased PA12 material in our production. Unlike conventional plastic materials, such as ABS or polycarbonates, this material is derived from renewable sources like castor oil and has a significantly lower carbon footprint. Biobased PA12 also has a longer lifespan and is more durable than other materials, making it a more sustainable option for eyewear.

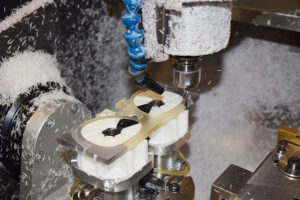

But our commitment to sustainability doesn’t end there. Our 3D printing production process is designed to minimize waste and reduce our environmental impact. Any excess material from the production process is salvaged and recycled, ensuring that nothing goes to waste. This eco-friendly production process does not just benefit our planet but also results in cost savings which we can pass on to our customers.

Here at Monvue, we believe that sustainability and style should go hand-in-hand. This is why we leverage 3D printing to create unique designs that are not just fashionable, but also sustainable. Our 3D printing production process enables us to make sure that only the exact amount of material needed to create the eyewear is used- this results in there being no excess material generated or wasted during production.

We take pride in the fact that we are a company that is actively taking steps to make a difference in the world through our innovative products. By making the switch to sustainable materials and production processes, we are doing our part to minimize our environmental impact and make the world a greener place.

If you are looking for high-quality, sustainable eyewear that features unique designs and modern aesthetics, look no further than Monvue. Contact us today and join us as we continue to lead the way in sustainable 3D-printed eyewear.

1. Vegan Leather case

2. Lifetime frame repair

Since durability and brilliant performance are top priorities for us here at Monvue, we’ve made sure that our frames are built to last.

For this reason, we back all of our frames for a 2 years from the date of purchase to protect you from any rare cases of manufacturing defects.

Ongoing efforts to further reduce waste

At Monvue Eyewear, we’re committed to reducing waste and making a positive impact on the environment. As a company that specializes in sustainable 3D-printed eyewear, we believe that every step we take towards reducing waste helps to create a healthier planet for generations to come.

One of the ways we’re doing this is by recycling the material that comes out during the production process of our 3D printing machines. This material is carefully collected and processed so that it can be used again, reducing our waste output and saving resources at the same time.

Additionally, we’re working hard to create packaging that is sustainable, reusable, and/or biodegradable. By making these changes, we’re reducing the amount of single-use packaging that ends up in landfills and oceans, and we’re doing our part to create a circular economy.

Steps taken to become a carbon-neutral company

But we’re not stopping there! We’re also committed to offsetting our carbon emissions by planting trees for every pair of glasses that we sell. This means that not only are we reducing our carbon footprint, but we’re helping to sequester carbon and promote healthy ecosystems.

We believe that by taking these steps toward sustainability, we can make a real difference in the world. Join us in our mission to create eco-friendly eyewear that looks great and feels even better. Together, we can make a brighter, cleaner, greener future for everyone.